The World’s Leading Range of CMM Measurement Systems

For more than 50 years, Renishaw has delivered innovations that have become milestones in industrial metrology. From the original touch-trigger probe and motorised indexing head to repeatable stylus changing and modular scanning systems, Renishaw sensors for co-ordinate measuring machines (CMMs) have become the industry standard across all CMM makes and models.

Our 5-axis measurement product range represents the most significant step-change in measurement capability ever introduced, delivering unprecedented speed and flexibility.

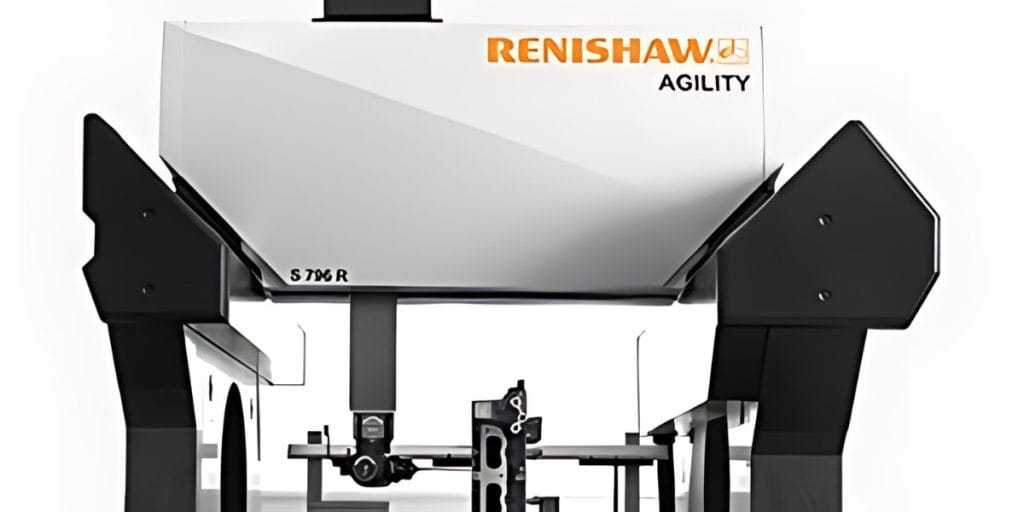

The latest generation of AGILITY® CMMs integrates award-winning REVO® 5-axis measurement technology, combining flexibility and production performance to deliver higher productivity in automotive, aerospace, and other demanding precision manufacturing sectors.

AGILITY® High-Performance CMMs

Renishaw’s AGILITY® range of high-performance CMMs brings the REVO® 5-axis measurement system to both the shop floor and laboratory environments. Designed for manufacturers who demand speed, precision, and repeatability, these CMMs combine robust build quality with cutting-edge metrology. By significantly reducing cycle times without sacrificing accuracy, AGILITY® systems enable faster throughput, more efficient workflows, and reliable quality control for industries where every micron counts.

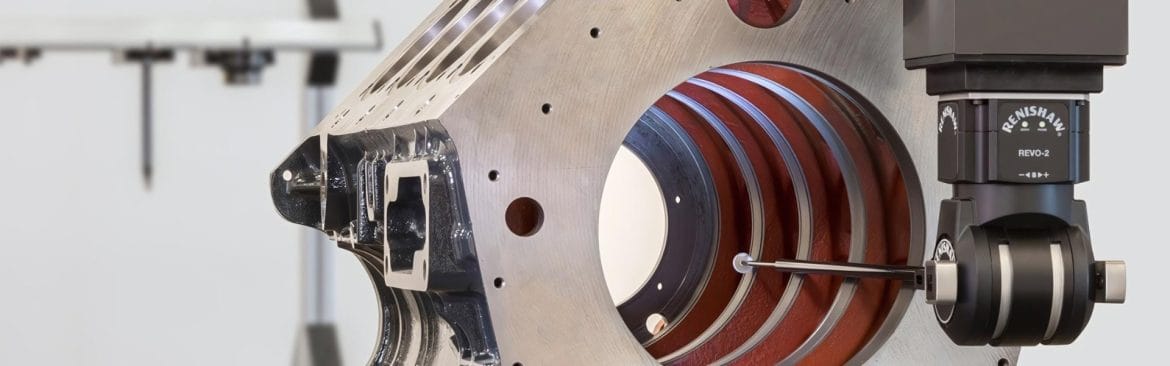

REVO® 5-Axis Multi-Sensor Systems

The REVO® 5-axis multi-sensor system revolutionises the way measurements are performed by combining multiple inspection capabilities into a single CMM platform. It supports high-accuracy tactile scanning, touch-trigger probing, non-contact optical measurement, ultrasonic sensing, and surface finish inspection — all without the need to change setups. By integrating all these functions into one machine, REVO® reduces part handling, optimises shop floor space, and captures more comprehensive data in less time, boosting both efficiency and product insight.

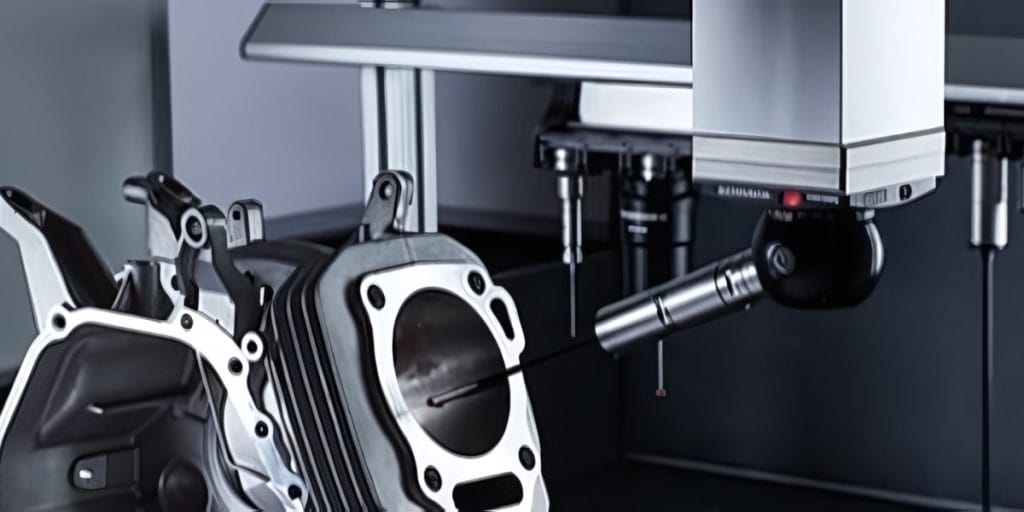

CMM Hardware

Renishaw provides the world’s most extensive range of touch-trigger and scanning measurement systems, stylus racks, and accessories for every type of co-ordinate measuring machine. From proven, industry-leading probes to advanced modular scanning heads, our hardware is engineered for seamless integration with your CMM. Each component is built for durability and precision, helping extend the capabilities of your system, enhance throughput, and maintain consistent measurement quality across all applications.

CMM Retrofits

Renishaw’s retrofit solutions breathe new life into existing CMMs, delivering modern measurement capabilities without the cost of a full machine replacement. These one-stop upgrade packages can include advanced probes, controllers, and software, instantly improving speed, accuracy, and functionality. Every retrofit is supported by Renishaw’s global network of engineers, ensuring professional installation, calibration, and ongoing support — allowing your CMM to meet today’s productivity demands with confidence.

What is 5-Axis CMM Measurement?

Renishaw’s advanced 5-axis measurement technology combines head, sensor, and control innovations to deliver unparalleled speed and flexibility, while avoiding the speed-versus-accuracy compromises of traditional techniques. This approach increases throughput, shortens lead times, and provides manufacturers with a deeper, more comprehensive view of product quality.

Unlike systems with indexing heads or fixed probes, 5-axis motion enables the stylus to follow a continuous path around complex geometry without stopping to index. Intelligent control algorithms synchronise CMM and head motion, optimising probe positioning and minimising dynamic errors for superior results.

REVO® – 5-Axis Motion and Infinite Positioning Multi-Sensor System

With a wide selection of probes, the REVO® system offers unmatched flexibility. It can automatically switch between tactile scanning, touch-trigger probing, ultrasonic, vision, and surface finish measurement in a single setup. By integrating multiple sensors on the same CMM reference frame, REVO® reduces the need for dedicated inspection systems, increasing productivity while lowering equipment and maintenance costs.

This all-in-one solution minimises part transfers between stations, reduces scrap, and optimises floor layout — resulting in faster inspections, greater accuracy, and improved energy efficiency.

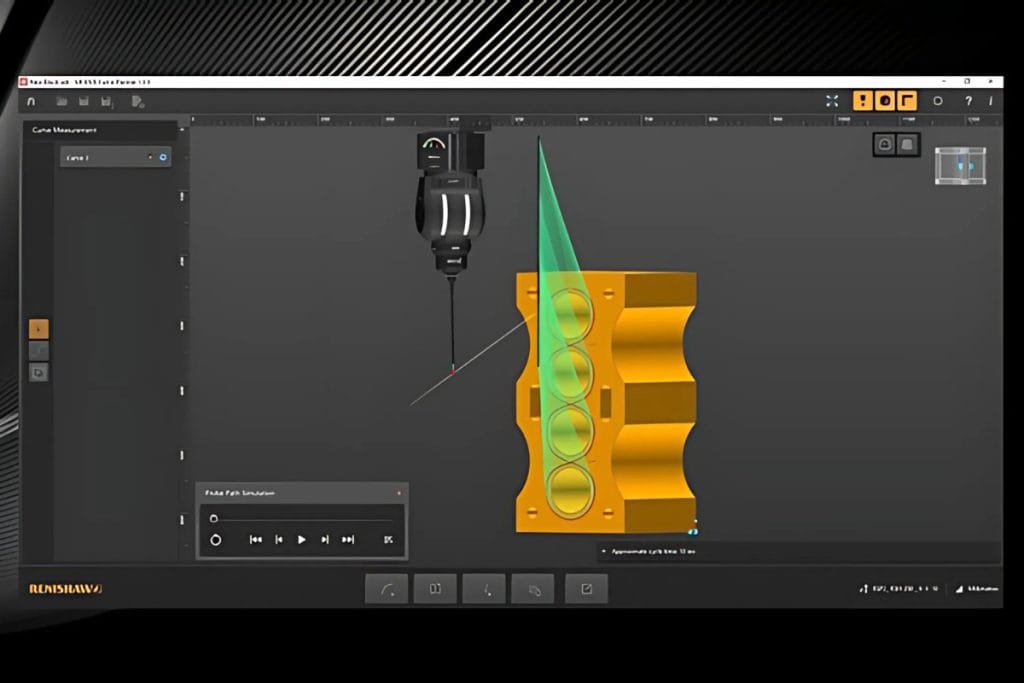

MODUS™ Metrology Software Suite

Renishaw’s MODUS™ Metrology Software Suite is a complete solution designed to maximise the performance of 5-axis CMM measurement systems. It consists of three powerful, complementary products:

MODUS™ Metrology Software – The core platform for creating and editing native DMIS programs offline, extracting geometry and tolerance data directly from CAD models. It incorporates certified feature measurement algorithms, advanced construction tools, and precise part alignment routines to ensure uncompromising accuracy.

MODUS™ Planning Suite – A streamlined, wizard-based programming environment for rapid 5-axis scanning setup. This tool simplifies complex measurement planning, reduces training requirements, and enables quick, reliable program creation even for intricate parts.

Blade Toolkit – A specialist module tailored for the inspection of turbine blades, blisks, and other complex aero-engine components. It allows CAD-driven measurement path planning and optimised DMIS program generation for highly accurate inspection of challenging freeform surfaces.

All three modules support offline probe path creation and simulation to minimise machine downtime. Built-in compatibility with current and future Renishaw sensors and controllers ensures that your software investment remains future-ready.

Unlock the Power of Your Data with Renishaw Central

Renishaw Central is an advanced smart manufacturing data platform that transforms raw CMM metrology data into actionable insights. By connecting measurement systems across the production environment, it enables real-time monitoring, faster problem identification, and data-driven process optimisation.

Manufacturers can track performance over time, visualise trends, and make informed decisions to improve quality, reduce lead times, and optimise resource usage. With Renishaw Central, measurement is no longer just about verification — it becomes a strategic driver for continuous improvement and productivity growth.

Why Choose Renishaw for Your CMM?

- Unmatched Innovation – Pioneers of 5-axis measurement and multi-sensor integration.

- Global Support Network – Installation, calibration, and service worldwide.

- Future-Ready Technology – Designed to evolve with your production needs.

Take Your Measurement Capability Further

Contact us today to discuss your requirements and see how Renishaw CMM solutions can transform your inspection process.