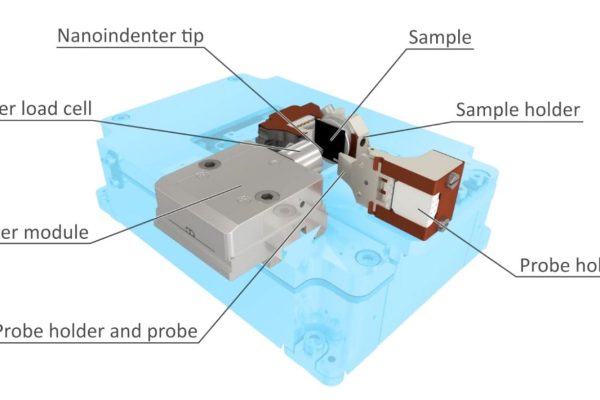

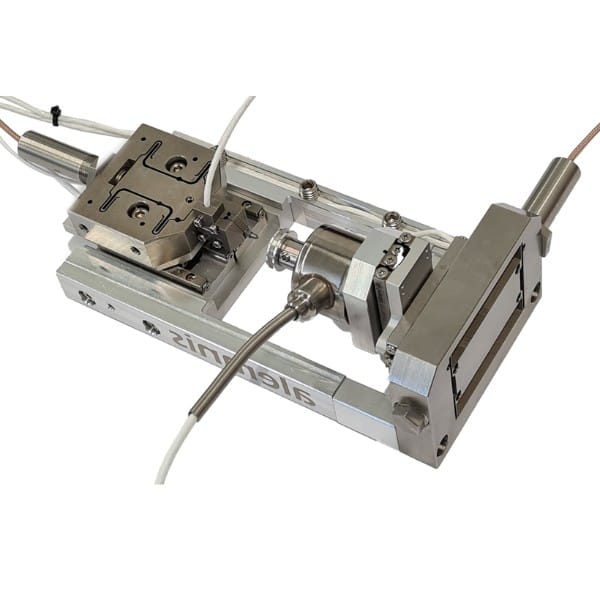

The ALEMNIS Standard Assembly (ASA) represents the forefront of precision mechanical testing at the micro- and nanoscale. Designed to accommodate a wide range of test types, environments, and integration platforms, the ASA delivers exceptional flexibility, robustness, and performance for materials scientists, engineers, and industrial researchers. Whether embedded in advanced imaging systems or operated as a standalone instrument, the ASA brings unmatched control and versatility to your lab.

CONFIGURATIONS OVERVIEW

The Alemnis Standard Assembly (ASA) is the world most versatile nanoindentation platform and can be configured in many ways for a vast ray of applications in many domains.

In-SEM Integration

The ASA is ideally suited for integration inside Scanning Electron Microscopes (SEMs), allowing for real-time observation of mechanical behavior at high magnification. This setup is invaluable for correlating structure with mechanical response in micro- and nanostructures.

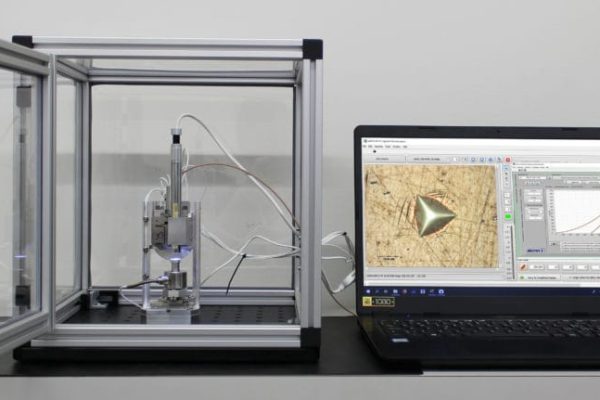

Standalone Operation

Outside of SEM environments, the ASA functions as a complete standalone mechanical testing platform, offering full environmental and parameter control, with seamless data acquisition. This enables high-throughput testing without the need for large-scale imaging equipment.

Automated Large Sample Platform (ALSP)

When combined with the ALSP, the ASA enables automated testing across larger samples or multiple sites with programmable precision. Ideal for large-area mechanical property mapping, it increases throughput while maintaining nanometer-level accuracy.

Micro-CT Compatibility

Integrated with micro-computed tomography systems, the ASA permits in-situ mechanical testing under 3D imaging. This is particularly valuable for analyzing internal structural changes during deformation in a non-destructive manner.

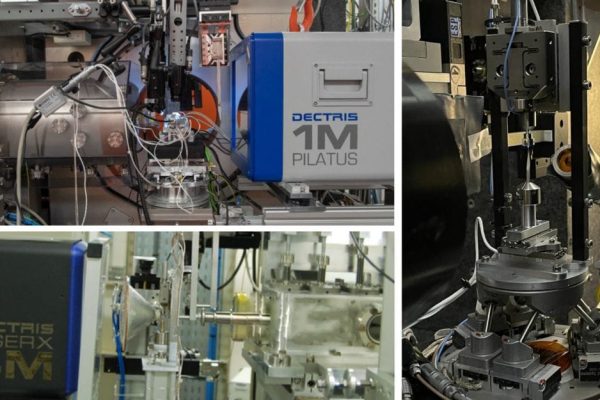

X-Ray Beamline Use

The ASA can be deployed at X-ray synchrotron beamlines, offering the ability to couple mechanical loading with high-resolution imaging and diffraction techniques. This setup provides insight into crystallographic changes and phase transformations during mechanical stress.

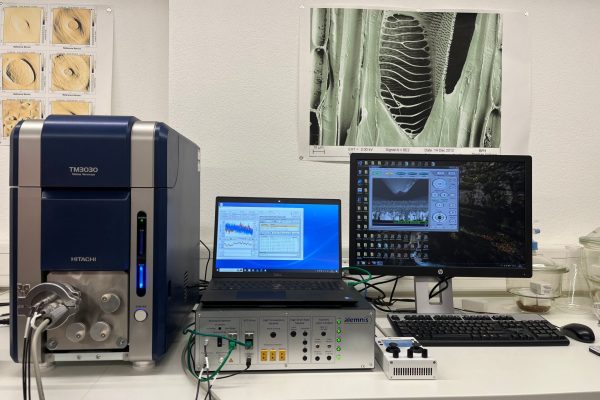

Compact Desktop SEM

Due to its compact and modular design, the ASA fits seamlessly into desktop SEMs, bringing high-end mechanical testing capabilities into smaller lab environments or field applications where space and mobility matter.

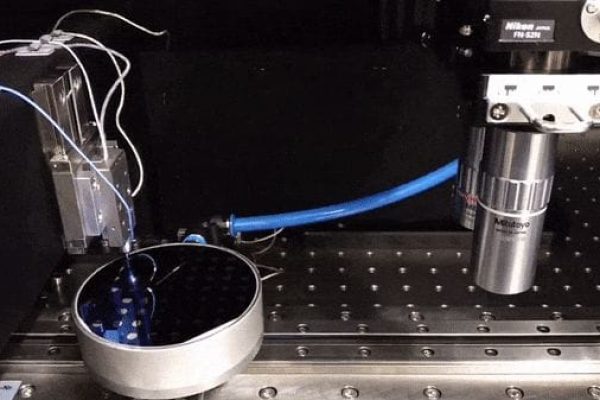

LightScope AFM Integration

The ASA is fully compatible with LightScope AFM systems, enabling correlative testing that combines mechanical measurements with high-resolution AFM imaging, broadening the scope of nanocharacterization.

Accessories

To unlock the full potential of the ALEMNIS Standard Assembly (ASA), a wide range of accessories is available to tailor the system to specific research needs. These high-quality add-ons enhance functionality, expand application possibilities, and ensure seamless integration with various test setups. From environmental control enclosures to precise gripping systems and advanced actuators, each accessory is designed to optimize performance, improve usability, and support the most demanding micro- and nanoscale experiments.

Standard Enclosures

Custom-designed enclosures are available to provide precise environmental control during mechanical testing with the ASA. These enclosures enable experiments to be conducted under tightly regulated temperatures, vacuum or inert gas atmospheres, and other specialized conditions, ensuring that sensitive materials can be tested without contamination or external interference. Whether your application demands cryogenic temperatures, high-temperature environments, or high-vacuum conditions, ALEMNIS enclosures maintain a stable and controlled setting to guarantee reliable and reproducible results.

Optical Microscopes

Integrated optical microscope modules extend the ASA’s capabilities beyond electron beam environments, offering visual feedback during sample alignment, positioning, and testing. These modules provide high-resolution imaging with adjustable magnification, facilitating precise navigation and monitoring throughout the testing process. Particularly useful in standalone setups or when combined with environmental enclosures, optical microscopes allow users to visually verify sample behavior in real-time, enhancing experimental accuracy and ease of operation.

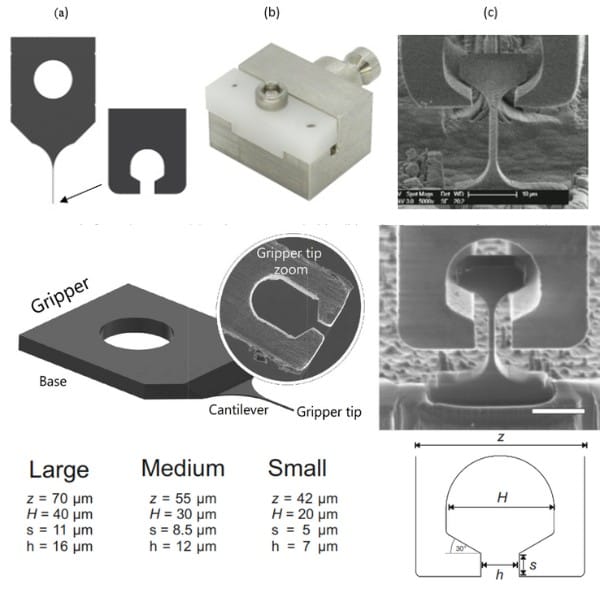

Tensile Gripper Systems

The tensile gripper systems from ALEMNIS are engineered for the precise handling and secure fixation of micro-scale samples during tensile testing. They ensure optimal sample alignment and controlled force application, which is critical for maintaining data integrity, especially when dealing with delicate MEMS devices, thin films, or micro-wires. The grippers are designed to minimize stress concentrations and slippage, enabling reliable tensile characterization even in challenging experimental setups where sample dimensions and tolerances are extremely small.

Tensile Fibre Clamp

Designed specifically for the challenges of working with ultra-fine fibers and filaments, the tensile fibre clamp provides a secure yet delicate method of holding nanoscale specimens. It maintains the structural integrity of the fiber during loading, ensuring that no artificial stresses are introduced during mounting. This accessory is critical for accurate tensile testing of materials like carbon nanotubes, polymer fibers, and biological samples, where handling sensitivity and mechanical stability directly impact the validity of the results.

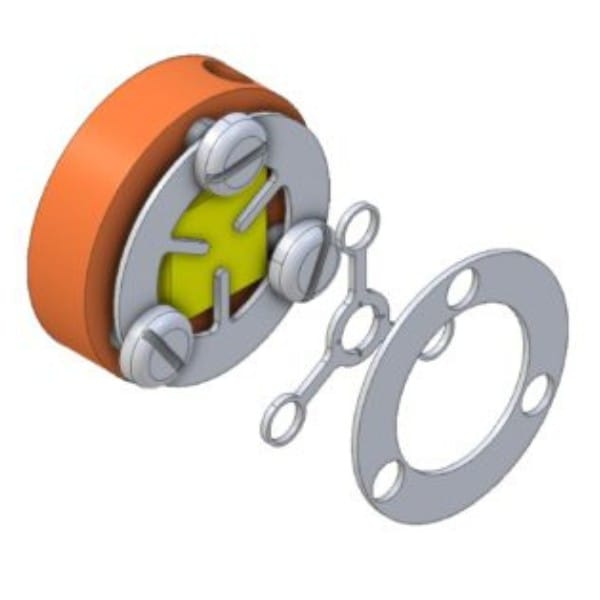

Sample Clamping Systems

Versatile sample clamping systems are essential for adapting the ASA to a wide variety of sample types, shapes, and testing configurations. These systems provide robust and customizable mounting solutions that accommodate irregular geometries, layered structures, or delicate microstructures. With modular clamp designs, researchers can quickly configure setups to suit specific test requirements, ensuring reliable sample fixation and minimizing artifacts caused by movement or misalignment during mechanical testing.

Piezo Actuators

High-performance piezoelectric actuators are a key component in achieving the ultra-precise displacement control required for micro- and nanoscale mechanical testing. ALEMNIS piezo actuators offer exceptional responsiveness, high dynamic range, and sub-nanometer resolution, making them suitable for both quasi-static tests and dynamic experiments requiring rapid loading and unloading. Their stability and precision enhance the reliability of force-displacement data, enabling cutting-edge research into material deformation and failure mechanisms at small scales.

Electrical Testing

Electrical testing modules allow researchers to simultaneously measure mechanical and electrical properties during in-situ experiments. This capability is crucial for studying piezoelectric materials, conductive polymers, MEMS devices, and semiconductors, where mechanical stress can influence electrical behavior. With ALEMNIS solutions, users can apply electrical signals, measure resistivity, or monitor current flow while performing mechanical deformation, providing a more comprehensive understanding of the coupled electromechanical properties of advanced materials.

Scratch Testing Stage

The scratch testing stage enables the study of surface properties such as adhesion, wear resistance, and coating durability under controlled mechanical loading. By applying precise and repeatable scratch motions, researchers can evaluate how thin films, protective layers, or surface treatments respond to mechanical damage. Integrated with real-time observation through SEM or optical microscopy, this stage provides valuable insight into failure modes, critical load thresholds, and the overall mechanical integrity of surface-engineered materials.

Load Sensors

ALEMNIS offers a selection of interchangeable load sensors designed to cover a wide range of force measurement requirements, from nano-Newton to Newton levels. These highly sensitive load cells deliver precise and accurate force readings, ensuring that tests are conducted within the optimal measurement range for the material and application in question. Their modularity allows users to quickly switch between sensors depending on the test type, maintaining both high sensitivity for delicate samples and robustness for more demanding mechanical tests.

Test Methods

The ALEMNIS Standard Assembly (ASA) supports a comprehensive range of test methods, enabling researchers to explore material behavior under a wide variety of conditions. From compression and tensile tests to nanoindentation, fracture toughness, and dynamic mechanical analysis, the ASA offers precise control and high-resolution measurements across different environments, temperatures, and strain rates. Its versatility allows for both fundamental research and advanced industrial applications, making it a powerful tool for understanding mechanical properties at the micro- and nanoscale.

Micropillar Compression – Enables precise deformation studies on micron-sized pillars to evaluate mechanical strength and size effects.

Ultra High Strain Rate Testing – Captures mechanical behavior under rapid loading conditions, simulating real-world impacts.

Low Temperature Testing – Allows materials to be tested under cryogenic conditions to assess brittle behavior or superconductive responses.

High Temperature Testing – Enables testing up to 1000°C or more, revealing high-temperature stability and phase transformations.

Tensile Testing – Performs micro-tensile measurements with high accuracy to study ductility and tensile strength.

Nanoindentation – Delivers precise hardness and modulus measurements at the nanoscale.

High Temperature Nanoindentation – Combines nanoindentation with elevated temperatures for studying thermomechanical behavior.

Mapping – Automated property mapping across sample surfaces offers spatial resolution of mechanical performance.

Beam Bending – Assesses flexural properties and fracture behavior in slender micro-specimens.

Fracture Toughness – Evaluates resistance to crack initiation and propagation in miniature samples.

Fatigue Testing – Investigates cyclic loading effects and durability at the microscale.

Creep – Measures time-dependent deformation under constant load and elevated temperature.

Stress Relaxation – Analyzes how materials dissipate stress over time after initial loading.

Scratch Testing – Evaluates surface wear and adhesion through controlled scratching experiments.

Tribology – Studies friction, wear, and lubrication properties at small scales.

DMA – Dynamic Mechanical Analysis characterizes viscoelastic behavior across frequencies and temperatures.